Guide to Emergency lighting

Mymesh Guide to Emergency Lighting

Emergency Lighting is an essential element of a lighting installation for the safety of the building. And after several recent fatal events in the last years, there is more and more attention for compliance.

A control system plays a vital part in the system. It makes sure it reduces maintenance cost, improves operation and ensure compliance. But most important, it keeps the occupants save.

Mymesh supports Automatic Self Testing

Introduction

Emergency Lighting is required in buildings to avoid darkness when the general lighting fails. The aim is to give illumination for orientation and allow personnel to find the escape routes without danger. Emergency lighting should operate automatically and result in sufficient lighting levels to evacuate safely.

The British Standard BS 5266-1 gives clear guidelines on how to design and install emergency lighting in a variety of applications; including, but not limited to, hotels, hospitals, care homes, schools and offices.. The standard recommends the necessary parameters for each category. Nevertheless, these requirements are a minimum and certain installations and/or clients may require or request higher standards.

Different categories of emergency lighting

Emergency lighting is subdivided into two categories:

- Emergency escape lighting provides illumination for the safety of people leaving a location or to shut-down a (potentially dangerous) process safely. This category is further subdivided into 3 groups. These are as follows:

- Escape route lighting – emergency lighting that identifies the escape route and ensures it can be navigated safely.

- Open area lighting – emergency lighting that gives a general lighting level to avoid panic and to enable identifying and getting to the escape route.

- High risk task area lighting – emergency lighting that gives a (higher) lighting level to provide safety when handling critical procedures to shut-down operations.

- Standby lighting provides lighting to continue normal activities unchanged. This category of emergency lighting is not a legal requirement.

Types of Emergency lighting

Power supply

There is a choice to be made for the type of Power Supply; Self-contained or Central Battery. There are several considerations when deciding which option is the better choice; with investment and maintenance costs being some of the significant factors.

Self-Contained – Single Point

Advantages

- Fast (and cheaper) installation

- Less invasive installation for retrofit

- Standard wiring material

- Mains cable burn-through will automatically satisfy the requirement for a luminaire to be lit

- Low maintenance costs

- Low hardware equipment costs

- High system integrity as emergency luminaires are independent (no single point of failure)

- Scalable (with additional luminaires)

Disadvantages

- Batteries may be adversely affected by a relatively high or low ambient temperature

- Battery life is limited to between 3 and 10 years

- Testing requires isolation and observation of luminaires on an individual basis (if no Automatic Self Test (AST) and Monitoring system is used)

Central Battery Source

Advantages

- Easy maintenance and routine testing is easier (only one location)

- Batterylife is between 5 and 25 years, dependent upon type

- Luminaire can operate at relatively high or low ambient temperatures

- For larger installations: large batteries are cheaper per luminaire and luminaires are more cost effective

Disadvantages

- High capital equipment costs

- Fire resistant cable makes the cost of the installation and system wiring high

- Poor system integrity as the failure of battery or wiring circuit can disable a large part of the system

- Requirement for a ‘battery room’ (including possible requirements for ventilation, climate control)

- Localised mains failure may not trigger emergency lighting

- Voltage drop on the long wiring

Compliance

The European Standard and BS 5266 both require two pieces of written declarations of compliance. The first documented legislation required is a ‘Completion Certificate’ which should be supplied by the installer. This includes a successful test of operation with a log of the system test. The second part needed is the evidence of regular (monthly and yearly) testing of the installation. This test simulates a mains power failure and activates the emergency lighting system to operate on the battery supply. This test can be carried out manually or automatically.

Testing of emergency lighting

Functional operation of the emergency lighting should be checked at least once every month. A full test should be performed at least once annually. The standard requires you to perform this test while the building is empty or at times of minimal risk, or test alternate luminaires at any one time.

Regular servicing by a qualified person is essential for the correct performance of the system. This includes the replacement of batteries at the end of life.

All results of the testing must be recorded and logged. Detected failures must be repaired as soon as possible.

The testing may be performed manually, but can be subjected to the trained individuals availability. If the responsible person is unable to ensure that this will be done as frequently as required, it is advisable to use an automatic test system to perform the tests at the required intervals.

Manual testing

A mains failure is simulated by isolation the mains circuit or the individual luminaire. Correct operation of each emergency luminaire must be checked. This means that the tester needs to walk the whole building, where emergency lights are present, to witness correct performance of the emergency lighting. After restoring mains power at the end of the test, the tester must complete this again to verify correct charging of the batteries. This is usually dictated by a green LED.

The cost of manual testing can be significant.

CIBSE Journal estimated the cost for the monthly mandatory test at £200 for an installation with up to 30 fittings. However, alternative methods can make it difficult for the building owner to be assured that it has been done correctly. All results gathered must be logged in the fire safety logbook, for reference.

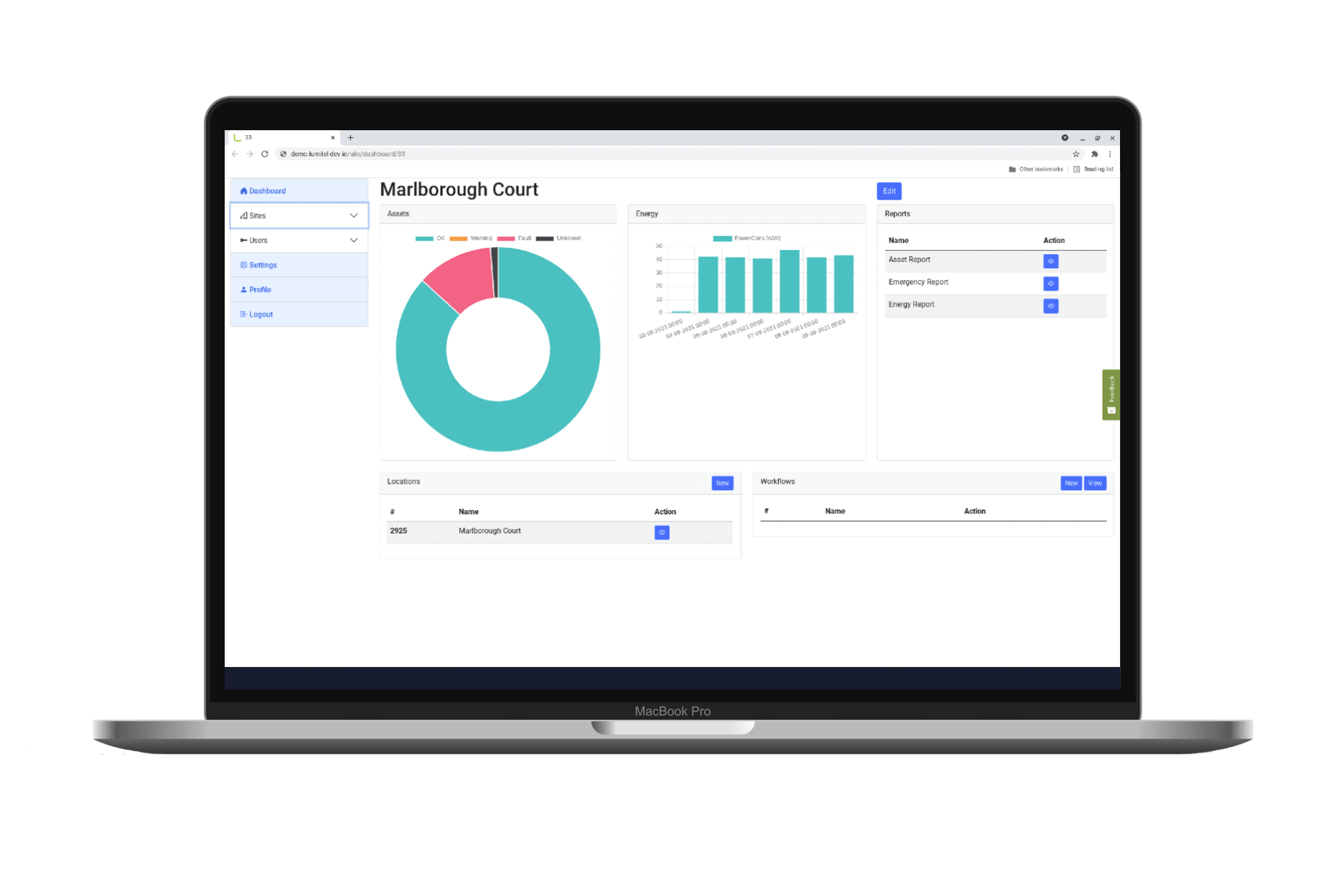

Automatic testing with Lumitel

To avoid the disruption, higher cost and compliance risks of manual testing, it is advisable to use an automatic test system to perform the tests at the required intervals. The Lumitel Cloud Dashboard can take over the execution, monitoring, reporting and guarantee compliance while being fully automated.

The Mymesh system uses DALI communication with the emergency inverter to control and monitor the Emergency Lighting. The following aspects are covered:

Testing

There are 2 distinct approaches; scheduled and randomised. The Emergency Inverter can be an automatic self test (AST) type that randomises the testing. This is a de-central approach that is very robust. The inverter will ensure that both Function and Duration Tests are performed in line with the testing regime required by the Standard. The lights require a 24 hour grace period after testing has occurred, so the randomised feature allows for the relevant lights in a section to be tested, while ensuring that the minimum required of emergency lights will still function during this grace period. This also allows batteries to recharge to a level safe for relevant legislation.

This will not always be acceptable in an installation. As a test will turn on the light, a randomized approach can be disturbing when the lights are required to be off. In these cases the tests can be instigated by the Mymesh system. This can be achieved via calendar functionality, determining when is best for the emergency tests to occur, minimising disruption. The time and date(s) chosen must be at a suitable time to ensure the disturbance potentially caused is at a minimum. To further reduce this, alternating sets of luminaires can be scheduled at different times.

Monitoring

The Mymesh system will continuously monitor the status of the Emergency Lighting. This will ensure that all test results are recorded. This also means that a fault status is observed as soon as it occurs. Furthermore, additional information like battery charge level and emergency time will be monitored. Luminaires are monitored continuously without the necessity for visits in person, saving money and time.

Compliance

For compliance it is required to record and log the test results. Lumitel will collect and store all data and present the results in a comprehensive report. This report can be retrieved from the Cloud based system or automatically be emailed to the user. Furthermore, all data can be retrieved from the data-log if required.

Predictive maintenance

Lumitel monitors the faults in the installation and will indicate if there are issues. This allows the system to inform the user to carry out required maintenance, and what exact maintenance is required. Time can be saved as both the type of the fault and the type of luminaire is known. The suitable parts can be brought to site, avoiding an expensive second visit.

Moreover, the data ascertained from the system can be used to accurately predict when maintenance would be required. Lumitel can also monitors battery charge level, temperature and for how long the battery was used. This can be used to estimate when a battery will need to be replaced. Doing this as group maintenance rather than individual spot replacements makes maintenance a lot more efficient.

British and European Standards for Emergency Lighting

The relevant standards

There is a series of British and European Standards that cover Emergency Lighting,including application, the system and the individual components. The key Standards are listed here, but this is not extensive.

Copies of the Standards can be purchased from BSI Shop - Buy British Standards.